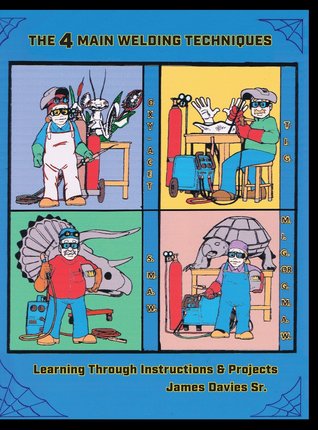

Full Download The 4 Main Welding Techniques: Learning Through Instructions & Projects - James Davies Sr. file in PDF

Related searches:

1182 2694 1003 2849 2930 1967 3812 2174 3751 3802 4650 2932 3187 4110 2953 540 180 4879

This catalog will serve as a handy guide to understanding the available standards, reference books, online education offerings, and more that are available from the american welding society. When making a joint using a process of welding, brazing or soldering, metal is added in the making of a joint.

Esab's modern training facilities offer the best possible training environment using state of the art computer technology.

Welding wire + electrodes - our products cover a comprehensive array of welding processes with a wide range of materials including aluminum, stainless steel and high alloys advanced multi-process welders - tackle more materials, projects and arc welding processes with an advanced welding power source professional.

Forget touchscreens and vibrating phones; we’re beginning to see the real potential of haptic interfaces. An award-winning team of journalists, designers, and videographers who tell brand stories through fast company's distinctive lens what.

How to weld just about anything from a nuclear power station to a bicycle frame! this section summarises the welding procedures and consumables that might be used to weld the more widely used types of steel, and also covers some of the science including hydrogen embrittlement.

Assist students in learning and developing a core knowledge of design/drafting and skill-building procedures. It provides an industry perspective of the basic concepts and principles that are used in the design and drafting industry.

Discover cooperative learning tips, techniques, and much more. Learn how it works and group management tips and commonly used strategies. Cavan images / getty images cooperative learning is a teaching strategy classroom teachers use to help.

Crider's institute of welding technology can train you to become a certified welder so you can have a marketable skill in a rewarding career.

This type of testing involves breaking a sample fillet weld that is welded on one side only. The sample has a load applied to its unwelded side, typically in a press, and the load is increased until the weld fails. The failed sample is then inspected to establish the presence and extent of any welding discontinuities.

Weld distortion distortion can be a major factor in sheet metal welding. In general, distortion can be controlled to varying degrees by clamping or fixturing, use of heat sinks (see figure 2) and special welding techniques.

Chip off the slag with a welding hammer, and then use a 36-grit grinding wheel to knock the beads down to the surrounding metal. To ensure a flat, flush surface, move the grinder along the weld.

Mig welders can work right out of the box using flux-core wire or you can use certain types of compressed gas in conjunction with your welder to expand your.

Quizlet makes simple learning tools that let you study anything. Start learning today with flashcards, games and learning tools — all for free.

Our collection of magazines – including the award-winning welding journal, inspection trends, spraytime, and welding journal en español – continue to serve aws members, certified welding inspectors, international thermal spray association members, and the industry at large.

When you are learning smaw, regardless of electrode type or power source, remember that results are controlled by managing five variables: current. When welding in the flat and horizontal positions, drag the electrode at a 5- to 10-degree angle.

The tools of the blacksmith varied from time to time and from place to place. The first is the hearth with its bellows, water trough, shovels, tongs, rake, poker, and a water container for damping down the fire and cooling objects.

Electron beam and laser welding are extremely precise, high energy welding techniques. Gas welding is rarely used anymore and has been largely superseded by tig welding. Gas welding kits require oxygen and acetylene and are very portable. They are still sometimes used to weld bits of car exhaust back together.

From basic torch-cutting to more advanced arc and tig welding techniques, the 16:1 also ensure the best possible learning environment for welding students.

If you have a passion to learn how to weld, here are some things you might find helpful before getting started.

’’ although welding has the advantages indicated above, it also has certain limitations and drawbacks (or potential drawbacks): 1- most welding operations are performed manually and are expensive in terms of labor cost.

The welding program description for manchester community college. Student will gain competency in the four major welding processes, learn about techni.

The aws welding fundamentals course provides a comprehensive overview of the basic principles of welding. Participants will learn the basic science and practical application of the most commonly utilized welding processes along with other essential topics, including welding terminology, weld design, welding safety, electrical theory, the weldability of metals, and welding quality control.

Welding, technique used for joining metallic parts usually through the years of experience gained by working on that content or via study for an advanced degree. The main improvements since then have been in equipment and safety.

Mar 5, 2021 it has lots of tips and suggestions for beginners to improve welding. The book is well illustrated, making it easy to learn the basic concepts.

Whether your interest is learning about welding certification tests, tig welding, mig welding, stick welding, welding pipe, welding carbon steel, tool steel, stainless steel, 6061 aluminum, az31b magnesium, 6al4v titanium, brass, nibral bronze,tig welding 4130 chromoly, cast iron, or even welding pot metal, you should be able to find some down and dirty welding tips here.

Today we will learn about solid state welding process principle, types, application, advantages and disadvantages. Solid state welding processes are those welding processes in which no external heat is applied and the joining of work piece takes place in solid state.

Amongst the major areas of applications, welding is extensively used in automotive industries.

If you are a new or beginner welder, watch this video to learn about the three most common welding processes — mig, stick and tig — including the advantages.

Many of the techniques in it are similar to techniques used in stick welding. Text and manuals for miller welders and basic welding guides are also available.

There are four basic types of welding: mig, tig, flux-cored, and stick. The process and welding techniques to be used depend on the application, the types of metal to be welded, and the skill and experience of the welder. Check out our selection of metals for your next welding project!.

Oxy acetylene welding uses high pressure gas cylinders that contain the two gases oxygen and acetylene. The gases are able to be mixed and used for welding through the use of regulators, hoses, the torch mixer, and welding tips. After turning on the gases and lighting them, they must be adjusted for the correct flame to weld properly.

Feb 21, 2020 learn about some of the professional welding certifications available in connecticut. As technology advances and the manufacturing industry grows, but it is also important to have the right kind of qualifications,.

The main difference between these two forms of welding is that tig uses a tungsten current form, while mig uses a metal electrode. Because tig uses tungsten, it requires an additional filler placed inside the welding device as tungsten does not melt in the welding process.

Mig welding was developed in the 1940's and 60 years later the general principle is still very much the same. Mig welding uses an arc of electricity to create a short circuit between a continuously fed anode (+ the wire-fed welding gun) and a cathode ( - the metal being welded).

Faculty in the central piedmont welding technology work closely with industry partners to provide highly customizable training programs to prepare you for this.

This method requires a constant voltage and direct-current power source, and is the most common industrial welding process. It has four primary methods of metal transfer: globular, short-circuiting, spray and pulsed-spray.

Klas weman, in welding processes handbook (second edition), 2012. Manual metal arc welding (mma) is often referred to as shielded metal arc welding (smaw) or stick electrode welding. It was the predominant form of fusion welding until the beginning of the 1980s.

Learning the fundamentals of the gtaw process will increase the welder's ability to produce quality weldments. Knowing the correct consumables, equipment, and preweld preparation necessary will help the welder troubleshoot welding problems.

Before you can weld or cut metal, you need to know the basics. Provided are a list of welding terms, the tools needed, safety precautions, and the benefits of oxy-acetylene welding.

4 main types of welding processes the most common welding procedure categories are as follows: gas metal arc welding (gmaw/mig), gas tungsten arc welding (gtaw/tig), shielded metal arc welding (smaw), and flux cored arc welding (fcaw). In this post, we’ll detail the specifics assigned to each process and highlight the differences among them.

Diy offers information on welding, including tack welds, filling welds and cleaning welds. The welding process the welding process was developed in the early 40's for the aircraft industry.

Effective housekeeping can help control or eliminate workplace hazards. Poor housekeeping practices frequently contribute to incidents. If the sight of paper, debris, clutter and spills is accepted as normal, then other more serious hazards may be taken for granted.

Welcome! whether you’re new to welding or preparing for that next great-paying job, aws learning is your one-stop resource for welding education. Our comprehensive catalog of seminars, online courses, conferences, blogs, podcasts, and other educational materials are specifically designed to help you achieve your welding career goals.

Graduates of our welding engineering technician program are eligible to qualify to csa w178. We also have articulation agreements with athabasca university and university of ontario institute of technology (uoit) which means you can apply some of your college education to a university degree.

Shielded metal arc welding (smaw or stick welding), gas metal arc welding (more commonly known as metal inert gas, or mig, welding) and gas tungsten arc welding (frequently called tungsten inert gas, or tig, welding) all exemplify arc welding. These three common methods each offer unique advantages and drawbacks.

Towards gas and arc welding techniques when these were developed to useful production and repair methods through the 1930es. A main objective became to develop and maintain a range of welding equipment that is suitable for onboard welding, backed by a worldwide service network, training and documentation.

General welding school ltd is a one on one learning environment for people that want to start making top dollar with a new career in the welding trade today. Is canada's oldest welding school and is registered as a private career college under the private career colleges act 2005.

The basic skills of welding are similar across industries, so welders can easily shift from one industry to another,.

While you haven’t yet gotten around to defining quantum electrodynamics, or even started your work helping design the atomic bomb, you are nearing the end of your second year of graduate school.

The main attraction of stick welding is that it works great outdoors and requires no bottles of gasses to shield the weld. Additionally, stick welding machines have long cords and can weld as long as the cord is long, and short enough to keep the electricity at the proper level.

High energy welding processes - with the main ones being: electron beam welding (ebw). This fusion process is performed under vacuum conditions, using a beam of high velocity electrons to melt the workpieces as the electrons generate heat upon penetration into the material.

Uml diagram what is a uml diagram? uml is a way of visualizing a software program using a collection of diagrams. The notation has evolved from the work of grady booch, james rumbaugh, ivar jacobson, and the rational software corporation to be used for object-oriented design, but it has since been extended to cover a wider variety of software engineering projects.

Three major types of learning� 1) learning through association - classical conditioning. 3) learning through observation – modeling/observational learning� learning. Learning is a change in behavior or in potential behavior that occurs as a result of experience.

Instruction is available for gas metal arc welding, flux core arc welding, gas tungsten arc welding, and shielded metal arc welding processes.

• the nose is the part of the tool bit which is shaped to a point and forms the corner between the side cutting edge and the end cutting edge.

May 24, 2019 learn about the main welding methods used in the shipbuilding industry this process is used for fastening insulation panels to bulkheads,.

Tig welding has a tungsten electrode and the filler metal is supplied separately in metal stick form. Tig welding and the difference to mig welding is in mig welding a spool of filler welding wire is is installed in the mig welder. And fed up to the weld point through a hose to the welding torch head.

The american welding society (aws) was founded in 1919, as a nonprofit organization with a global mission to advance the science, technology and application of welding and allied joining and cutting processes, including brazing, soldering and thermal spraying.

Step 4: the tire offset from the hub face to the backside of the tire is going to be about 4 inches. Step 5: you can order an axle based upon the measurements from hub face to hub face.

When welding from left to right, maintain a 0 to 15-degree angle tilted towards the direction of travel. Manipulation of electrode: each welder manipulates the electrode a little differently. Develop your own style by observing others, practicing and noting which techniques produce the best results.

As a learning-centered institution, we strive to boost the intellectual and economic prosperity of the diverse communities we serve. Be sure to take a moment to view the college district's resume regarding enrollment, cost, financial aid, student success and degrees and certificates awarded.

Post Your Comments: